ORI collaborates with SENIOR FLEXONICS, the world’s leading company in the design and construction of expansion joints, for various applications in different industrial sectors.

SENIOR FLEXONICS is able to design and manufacture any type of joint, following the expansion joint manufacturers’ association (ASE) and the PED Directive (97/23 / EC), and to address and solve problems related to thermal expansion of pipes, finding the ideal solution for every specific requirement.

Our metal joints are made with different manufacturing methods, depending on the characteristics of the items (dimensions, materials used, thicknesses and number of walls, etc.). The methods used are therefore elastomeric conformation, hydraulic and mechanical conformation.

They are made of stainless steel and carbon such as AISI 321, AISI 316L, AISI 310 etc. or with special alloys according to the use they are intended as MONEL, HASTELLOY, INCONEL, etc.

Pipes are subjected to dilatations generated by different temperatures, pressures, external movements and the weight of the pipeline. Where the values of forces and movements exceed the acceptable values, it is necessary to use compensators that allow to absorb the different thermal expansion. In addition, load losses and thermal dispersions are contained, with special benefits especially on large diameter pipes. The joint must be selected and designed according to the operating conditions to fully exploit its functions.

Depending on the type of dilation that the joints can absorb, they are classified as:

Axial: Axial compensators, formed by one or more bellows, are designed and built to absorb axial movements. They are always installed between two fixed points so that they can support the thrust due to the internal pressure.

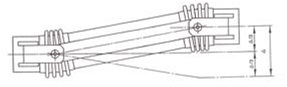

Universal: They have two bellows capable of absorbing any combination of movement: axial, lateral and angular. The difference consists in the fact that it does not have spherical rods and therefore is not capable of holding the bottom plane itself, but can also absorb axial movements due to expansion of the pipe as well as side movements on any plane such as the compensator spherical lateral.

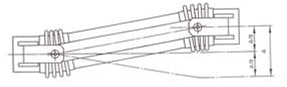

Angular spherical: The angular joint is the best solution when the races to be absorbed are very high; due to the angular movement it is possible to use the combination of 2 or 3 joints installed in certain configurations. To get the same result it would require a much higher number of axial joints.

Lateral: These double-hinged joints allow to absorb lateral displacements on the same plane.

Lateral spherical: The spherical side joints are complete with spherical washers positioned at the ends of the tie rods and allow to absorb lateral movements on all floors. Even in this case it is essential to install fixed points which, unlike previous installations, will not have to support the thrust due to internal pressure.

All models of joints can be supplied with optional equipment such as:

- Internal conveyor: To avoid direct contact between the bellows and the fluid, a conveyor is welded internally the joints which reduces thermal stresses, attenuates leakage losses, turbulence and erosion.

- External protection to protect the waves from extraneous bodies or to facilitate the application of the insulation the bellows can be wrapped externally by a carbon steel sheet.

- Reinforcing rings in cases where the bellows is subjected to high pressures, it is necessary to use reinforcement rings made of carbon steel. In addition to evenly distributing compensation, they also serve as racing limiters.

The advantages of using the joints are as follows:

- They require a small space for installation

- Their flexibility allows to absorb movements on more axes

- They do not require maintenance

- Minimum load loss and temperature drop.

Due to the continuous growth and technological development, SENIOR FLEXONICS has a great experience and remarkable strength in design and construction of expansion joints FCCU and RFCCU units and nozzles for nuclear plants installed all over the world.